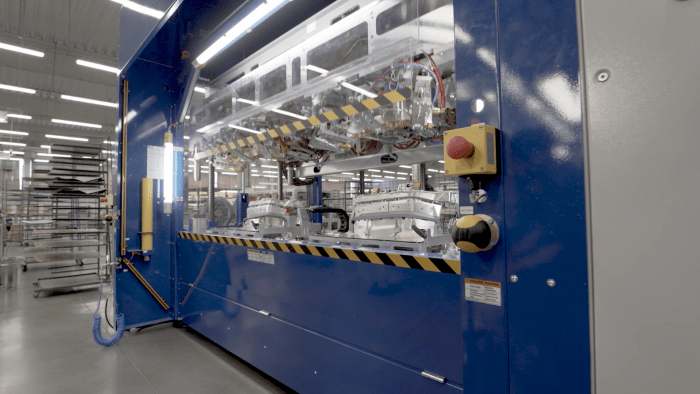

For high-volume production are used presses, where the upholstery takes place by a combination of heat and pressure. We are using a high end machine by Frimo, which enables the simultaneous establishment of coating material behind the visible edges of interior parts. This ensures the highest-possible level of stability and repeatability of the processes, which goes hand in hand with reaching the highest levels of quality of finished products.

As in the case of hand upholstery, water-based dispersions of crosslinking polyurethane adhesives are mainly used with regard to the environment.

Gallery

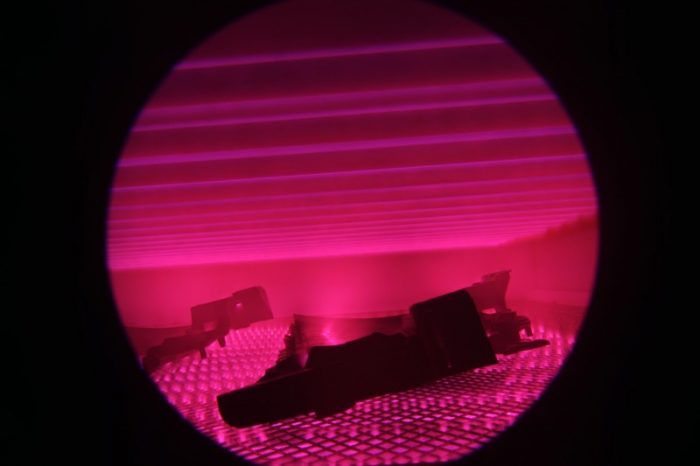

Plasma treatment of plastic surfaces

In a special chamber by Tantec, we activate and modify the surface of non-polar plastics (PE, PP) with low-pressure plasma. Plastic parts with such a surface can then be printed, varnished and covered with materials in all conventional ways , which significantly expands the usage possibilities of these processed plastics and reduces cost of these subsequent operations.